R&F Mechanical Services has played an integral role in the successful completion of the Translink Milewater Service Centre in Belfast.

The leading mechanical contractor was responsible for the delivery of the full M&E Package, this was successfully achieved by working closely with both Henry Brothers and subcontractor Braham Electrical. The main building comprises offices, meeting rooms and staff facilities (120,000ft2) across four floors. It sits alongside engineering garages and workshops, bus washing facilities, parking for 145 buses and 191 staff car parking spaces.

The main garage can accommodate up to 27 buses ranging from the smaller metro buses to double deckers and, of course, the extra-long new Glider fleet. The facility has its own in-house paint prep and spray booths allowing for complete repair of the fleet. With multiple bays having their own pits and specialist bus lifts, along with two overhead cranes, the workspace brings Translink into the 21st century compared to its previous facility just across the road.

A separate, dedicated engine workshop, tyre store and fabric covering workshop are just some of the parts that make up the building. It moves Translink’s existing stores to a new dedicated central store spread across three floors of the building, serving both this new facility and other Translink sites.

One of the key elements for R&F Mechanical Services was the co-ordination with specialist suppliers. The company is well-versed in commercial mechanical installations but this project included a number of unusual elements, with R&F Mechanical working closely with the suppliers of the high efficiency bus washing facilities as well as the bespoke diesel, specialist fuels, lubrication and antifreeze storage and distribution systems to serve the extensive Translink fleet.

The project also included elements such as vehicle exhaust extraction throughout the main garage facility, a dust extract system to serve paint prep and workshop areas, and a specialist gas supply to the welding workshop.

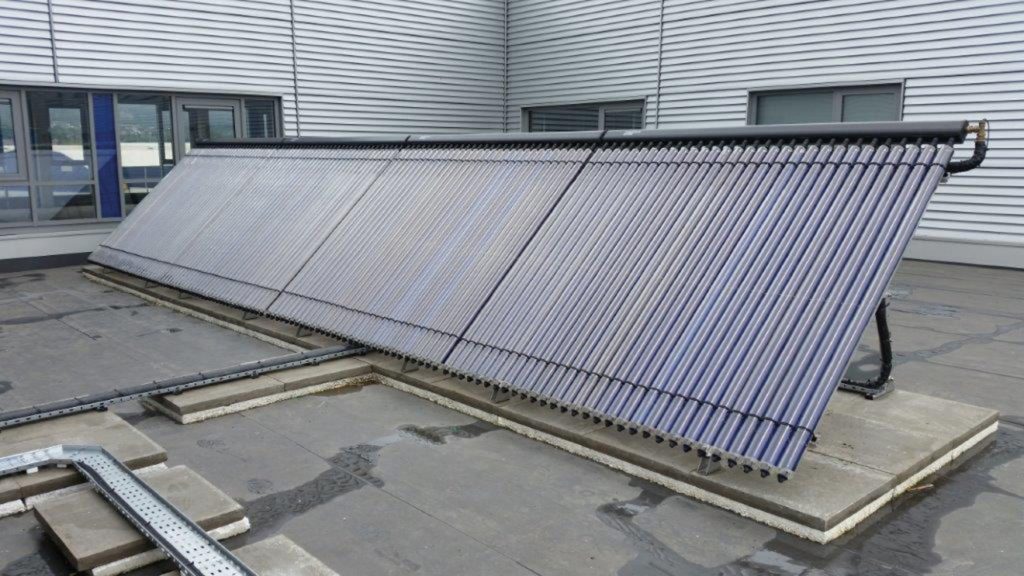

Energy efficiency was central to the project, and R&F Mechanical Services installed a solar array to feed the DHW system along with two rainwater harvesting tanks totalling in excess of 100,000 litres of rainwater reclamation as part of the bus washing systems. The entire mechanical system is incorporated into the overarching Building Management System (BMS).

R&F Mechanical Services Ltd, 13 Seymour Street, Ballymoney, BT53 6JR

T: 028 2766 2627

W: www.rfmechanical.com

Two systems were installed by the company – one for the boilers in the rooftop plantroom and another for the gas fired specialised pressure washer, used by staff at the Milewater Centre for removing dirt and grime from the bus’ wheels. All products specified for the project, including the boiler and flues, were of the highest standard and quality.

Significant preparation ensured a hassle-free installation on site. “A lot of the design work and pre-site works took place before we hit the site. We needed to get drawings designed up and approved by the mechanical contractor and main contractor so that any potential issues on site were avoided. Ensuring all that groundwork was completed correctly meant less work on site,” said Alan Todd, Project Engineer at John J Doyle Ltd.

Alongside quality workmanship from the team at John J Doyle, a high quality flue also helped ensure an excellent finish fully compliant with the European Standard for Chimneys EN 1856-1. Dinak DWJ flue was used by the team on the Milewater Service Centre. Designed for condensing (with joint) and dry (without joint) applications, the Dinak DWJ allows for thermal expansion to be absorbed in each element. John J Doyle Ltd has worked with the mechanical contractor on this project several times previously. “We’ve built up a really good relationship with the team at R&F Mechanical. That relationship helped ensure everything went smoothly on this project and we’re looking forward to working with them again in the near future.” Cooperation was the name of the game on this project.

“Getting those initial design drawings signed off by the main contractor, design team and mechanical contractor before we even got to site helped avoid any major hold-ups. The initial work that we put in paid off hugely.” John J Doyle Ltd is the UK and Ireland’s leading experts in the design, supply and installation of chimney systems and refractory engineering services. The company was established in 1928 on Eliza Street in Belfast by the grandfather of the current managing director. With over 90 years of experience, John J Doyle Ltd boasts an extensive track record of dependable workmanship and client satisfaction extending to a portfolio of top quality design, supply and installation.

Last year John J Doyle Ltd opened its first office in England. With the appointment of Roy Tregay as UK Contract Director, this office in Norwich allows for local communication with companies based in England, Scotland and Wales. The Norwich office is located at Oaklodge Business Centre, School Lane, Norwich, NR9 3LB and can be reached on 01603819137.

John J Doyle Ltd, Duncrue Industrial Estate, 5 Duncrue Place, Belfast BT3 9BU.

T: +44 (0)28 90 247864

W: www.johnjdoyle.com

Beggs and Partners provided the Armitage Shanks sanitaryware at Translink’s new Milewater Service Centre, as the company continues its excellent working relationship with R & F Mechanical Services. “This was a prestigious job for us to be involved in and we were delighted to work with R&F Mechanical Services once again,” said Beggs and Partners Group Contract Director, Alastair Scott.

The companies have already worked together on prestigious projects such as the Omagh Hospital and the Ulster Hospital and this relationship will continue as Beggs and Partners will provide the sanitaryware for Translink’s multi-modal hub at L’Derry. Part of this multi- million pound scheme will see the redevelopment of the former Waterside Train Station, a grade-B listed building and much-loved landmark in the city.

Beggs and Partners have also supplied the sanitaryware for the redevelopment of Portrush Train Station ahead of the 148th Open at Royal Portrush Golf Club this July. Two new platforms have been completed as well as extensions to Platform One and new station building enhancements.

Having formed strong business relationships with some of the biggest names in the industry, Beggs and Partners have supplied products to some of Northern Ireland’s most recognisable buildings including The Grand Central Hotel, The Lyric Theatre, Kingspan Stadium, the Causeway Visitor Centre, the Titanic Visitor Centre and the University of Ulster, Belfast. The Milewater Service Centre represented a medium-sized job for Beggs and Partners but it was one they were proud to be involved in.

The sanitaryware was supplied as specified and on budget. Beggs and Partners supplied toilets, wash troughs, urinals, vanity basins and Doc M Packs at the Milewater Service Centre. The new £20 million facility is the main base for Translink’s new Glider fleet as well as a new depot for Translink’s engineering and project teams.

It will support the Department for Infrastructure’s commitment to increase the number of journeys made by public transport.

Beggs & Partners, Great Patrick Street, Belfast.

T: 028 9023 5791

W: www.beggsandpartners.com

Branches at Belfast, Ballymena, Lisburn, Maghera, Newtownards and Portadown

Waterman Compliance Services Ltd carried out works at the Milewater Service Centre site on behalf of the mechanical contractor. Waterman completed a mandatory Risk Assessment to identify any potential risks in relation to legionella, backflow and cross contamination issues to assist the contractor with a smooth system handover.

Upon completion, Ross Black and the team at Waterman Compliance Services provided consultancy services and met with the builders to brief them on the potential risks and how they could be rectified where necessary.

“Our job was extremely straightforward in that the project build was carried out to the highest standard. It was a very good finish and any concerns we raised were addressed by the builder as soon as possible” said Ross, Technical Director at Waterman Compliance Services Ltd.

This was the first time the company had worked with the Mechanical Services contractor.

“We established an excellent relationship with R&F Mechanical Services Ltd on this project and have continued to develop our working relationship. It was great to be involved in such a prestigious project for Belfast and to work with such a committed, talented team.”

With over 30 years of leading industry experience through the Waterman Environmental Group, Waterman Compliance Services was the ideal choice when it came to ensuring that a thorough, competent and detailed water hygiene risk assessment was carried out.

The company provides total water hygiene control, water treatment management, and other environmental solutions to a wide spectrum of clients in both the public and private sectors throughout the UK & Ireland.

T: +44 (0)28 2816 3100

W: www.watermancomplianceservices.com

MIC Contracts were proud to play their part in the delivery of Translink’s new Milewater Service Centre.

The company, from Toomebridge, Co Antrim has a wealth of experience in industrial insulation for hospitals, schools, boiler houses and roof spaces so they were well equipped to carry out this contract at Milewater. MIC Contracts specialises in the supply and fit of systems from Saint Gobain Isover (formerly Moy Isover), Beta Plus, Paroc and Armaflex.

The company also specialises in pipe insulation, ventilation insulation, tanks and boilers, refrigeration and aluminium cladding.

“As a specialist thermal insulation contractor with some 40 years’ experience we get contracts from across the UK and Ireland, working on a wide range of sectors,” said Jason Carey from MIC Contracts.

The company takes the safety of its staff, other employees and the general public extremely seriously. All contractors are provided with the latest PPE safety equipment and have had extensive training on the company’s systems and construction site safety.

T: 028 7965 0163

W: www.miccontracts.co.uk

Established in 1887, Willis Heating & Plumbing was the obvious choice when it came to working on the underfloor heating and solar water heating element of the Glider project. Thanks to a long-established relationship with R&F Mechanical Services, Ian Steele and the rest of the team at Willis Heating & Plumbing were able to complete their package of works on time and to the highest quality.

For the past 30 years, the company has been using Uponor 20mm Pex Pipe for its projects around the country. “It’s one of the best pipes on the market, a high quality, top end system. It was the ideal choice for a project as prestigious as the Milewater Service Centre. For the solar water element of the project, we used Kingspan Evacuated Tube Panels, another highly efficient, durable product,” said Ian Steele, Director at the company.

A smooth, hassle-free process helped the Willis team finish on time. “We didn’t encounter any particular challenges on this project. We’ve been operating for a very long time so we’re well used to working on projects like these. The relationship that we’ve built up with R&F Mechanical and the collaborative approach the two companies take on every project we work on also helped get us over the line,” said Ian.

Willis Heating & Plumbing is no stranger to prestigious projects. The company has just finished working on Hillsborough Castle and currently has several other large-scale projects on its books.

“We’re delighted to have been involved with the Milewater Service Centre and we’re proud to have contributed to such an important project for Belfast.”

T: 0044 (0)28 9078 1236

W: www.willis-heating.com

Whitehouse Engineering was proud to play its part in the development of Translink’s new Milewater Service Centre in Belfast.

The company, from Mallusk, Newtownabbey, Co Antrim, installed the office and workshop HVAC systems at the new state-of-the-art complex.

CIAT and Swegon air handling units along with Dunham Bush fan coil units and Mitsubishi Lossnay heat recovery units were supplied and installed as part of the HVAC systems. “This was a straight forward project which didn’t present us with many technically difficult challenges,” said Whitehouse Engineering Managing Director, Stephen Dawson.

“All our working drawings for the project were created in our in-house drawing office using the latest BIM software which enabled the HVAC services to be closely coordinated within the building structure.”

“In terms of the project itself it was a good one for us to be involved with, and it was pleasing that we have played our part in the development of the Province’s transport infrastructure.

“The glider buses are a step forward in terms of improving our public transport and it was a satisfying project for the company to be involved with.”

The new £20 million facility is an integral part of the Glider network. It will also act as Translink’s central storage facility and workshop, maintaining the standard bus fleet alongside the Glider vehicles as well as being home to over 100 Translink staff members and specialist engineers and project teams.

T: 0044 (0)28 9084 8311

W: www.whitehouse-eng.com

ENERGYTECH NI Ltd was tasked with the commissioning of all the gas- fired heating equipment at the Translink Milewater Service Centre. This included the commissioning of Ambirad Radiant Tube systems in the main workshops and warm air heaters in the smaller areas.

The company was also responsible for commissioning the Remeha boilers in the admin areas.

Energytech has commissioned these systems at several other prestigious jobs, including Northshore Film Studios and Porsche Showroom, Belfast.

The company was delighted to work with R&F Mechanical on this project.

T: +44 (0)28 388 70507

W: www.energytechni.com

Gas & Controls Ltd delivered the gas detection systems throughout Translink’s new Milewater Service Centre. The company, from Carrickfergus, Co Antrim spent a lot of hours on site but in the end the job was delivered on schedule.

Contracted by R&F Mechanical Services Ltd, Gas & Controls Ltd carried out commissioning and installation work at Milewater. “The job went very well, it was a quick-moving project but we are very pleased with the outcome,” said Gas & Controls Ltd Operations Manager, Mark Whitehead.

“The job was split into two sections. In the plant room we used a S&S gas detection panel and then in the other areas where 52 | PLUMBING & HEATING MAGAZINE there are overhead heaters such as the main building, the works area and the bus-wash area we used the Oldham Sample System.”

The gas detection systems used by Gas & Controls Ltd, which are tailored to each individual job, work by detecting any natural gas leaks and then shutting down the gas supply to that area effectively isolating the leak.

Gas & Controls is one of Ireland’s fastest growing gas detection and environmental monitoring companies. Using state-of-the-art gas safety technology along with 30 years of experience in this industry the company provides high quality commissioning and maintenance service of gas safety systems throughout Ireland.

T:+44 (0)28 9335 0425

W: gasandcontrols.com